You could be forgiven for thinking

now that I do not like Nurbs! Ha hah - well sorry to disappoint you but I think Nurbs are

great! They are brilliant modeling tools when required. But they must - like everything -

be used with discretion and wisely.

Generally a Nurbs mesh should be left as a

Nurbs mesh for layout if the final requirement is deformations within layout - i.e.

character meshes - animal meshes etc..etc.. by their very nature they need to be Nurbs to

be animated properly.

Sometimes also in my career some very fluidic

organically shaped hard body models have been kept Nurbs to allow the animators some

level of discretion when it comes to rendering. They can for example set the mesh to a

render level of just 1 for background shots and then up it to say 6-8 the closer the mesh

gets.

However 80-90 percent of the time additional

surface detailing of such mechanical objects makes this method vastly impractical to

employ, because the resultant polygon counts when it comes to freezing and tripling the

Nurbs object can and does approach millions; because of the surface

detailing - which by the nature of this method has all had to be added as

Nurbs!

No, it is best practice to do the

following... If the mechanical object you are creating has a very organic feel

to it or indeed you are trying to replicate the smoothness of say an injection molding;

then by all means make it with Nurbs but then use your head and freeze it. Optimize it by

using methods such as bandglue and the like, and streamline the model then for rendering.

Triple the resultant patches of non-planar's that result from the freezing and then begin

adding details with the built in tools available such as - rounder - for

example, and 3rd party tools like Vertibevel.

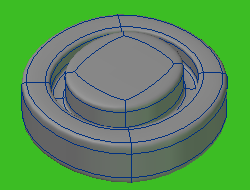

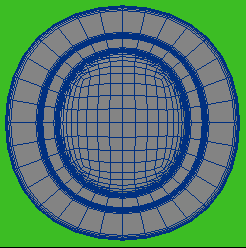

Let me give you some examples. I have created

a simple button - in this first example with Nurbs - astute viewers will note that I Have

used edge loops to control the radius of my edges in this Nurbs mesh. I could use point

weighting to control these radii (sp?) but there is an inherent problem with that - if

the mesh is to be used purely in Lightwave there will be no problems - but if exported

for other applications (which invariably

happens I guarantee you) then issues

arise - point weighting does not translate well into 3rd party applications! Not to

mention it doesn't behave properly when it comes to using catmull Clark within Lightwave

itself. The weighting can and does result in very different effects - so although edge

loops can add to the polygon count - it is mostly preferable.

Now this is supposed to be a mechanical round button - it should not be

left as a sub patch object for layout really as it will not deform - unless it

was say a rubber button - but it's not!  Now I have had to use a sub patch level of 8 to get rid of a

noticeable level of faceting on a simple cage like this - and the result when frozen and

tripled for rendering becomes:

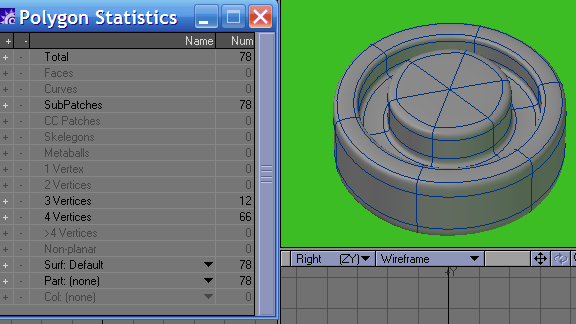

Now I have had to use a sub patch level of 8 to get rid of a

noticeable level of faceting on a simple cage like this - and the result when frozen and

tripled for rendering becomes:

.. a whopping 5,888 polygons from an initial

polygon cage of just 46 polygons!

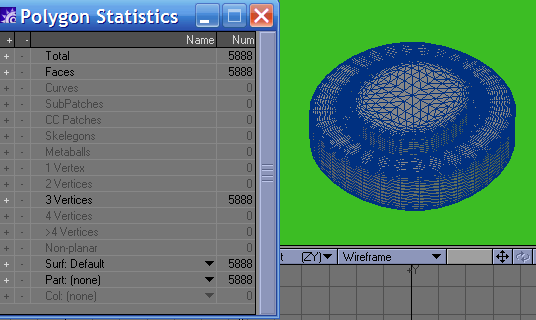

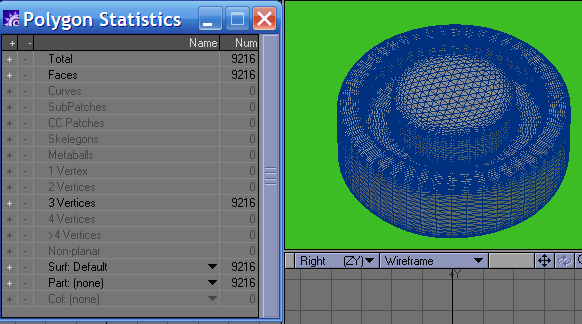

Now, in my pipeline I would, if I had used Nurbs to make this object;

frozen and optimised it with bandglue and gotten something along these lines:

...so that's a saving of 4,448 polygons but you

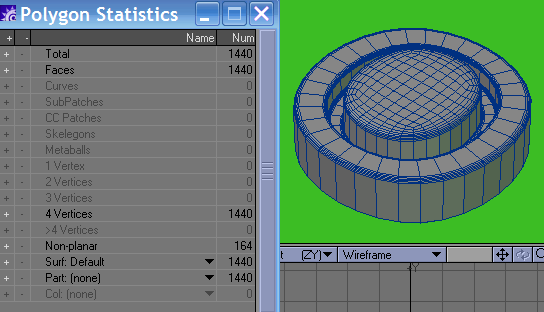

will note there are resultant non-planar's so I need to triple them:

...the end result is 1,604 poly's and a saving of

4,284 for this button now when it comes to rendering; and the net result

is it will render more or less exactly the same in appearance. However there is an issue we

have not resolved yet and that is with a cage so low, we are not getting a perfectly round

button! Look at this Top projection and you will see it more obviously.

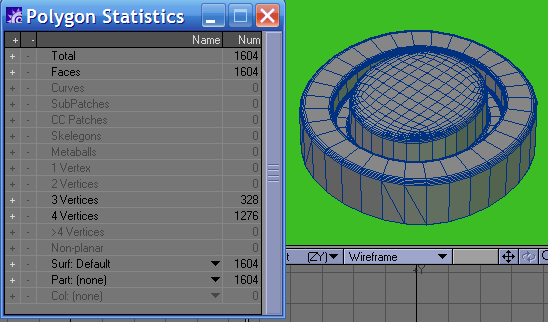

no, to get a more accurate approximation of a circular button we need

more polygons to start with - more along these lines in fact...

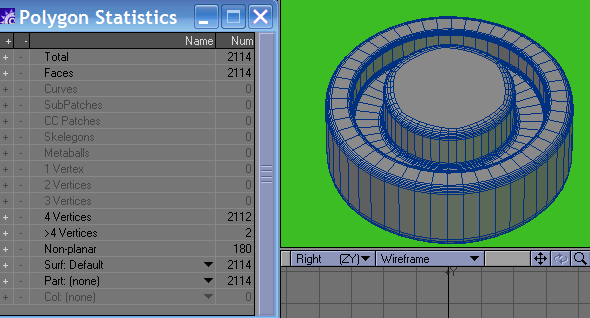

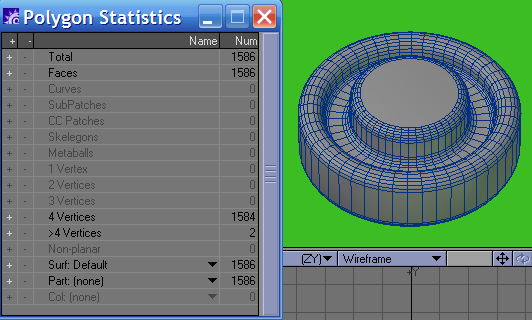

We now have a base cage of 78 polygons and this

produces this many polygons when frozen and tripled, if left as a Nurbs cage for

rendering:

or this many when frozen and optimized and taking care of the non

planar's in modeler prior to rendering.

But you know what? Even though this is now a more accurate

representation of a circular button it's still not perfectly circular! Plus

the polygon counts for a simple button - even a highly detailed one -is too much - imagine 50

of these on your panel! ;o)

Lets' try a different tactic now shall we? Lets make it with the disc

tool - some bevel ops' and rounder and see what happens?

a perfectly circular (well as circular as a 48 sided disc can

be) button with nicely defined radius edges - looks better and comes in substantially

less than even the frozen optimized version!

The lesson that needs to be learnt here is simple really - stop

using Nurbs to create cylinders and boxes - even if they have rounded edges and

rounded corners and the like - there are better tools for the job right there in the modeler

toolbox!

If you have a mesh that has a weird body shape (world war two tank

is a good example) make the base shape and freeze it! Then add details with Boolean,

stenciling, rounder and Vertibevel if you have it in your arsenal - they are better suited to

the job than Nurbs for adding that ancillary detailing and the polygon counts will be

drastically lower - allowing you to add more rich detail instead. think about

it....

Also when it comes to flatness or planarity - if your objects are mainly

flat - even if you then rotate that object - it will still be a flat object - then don't worry

about tripling or fanning by hand - let Lightwave take care of that for you - it only really

becomes an issue with objects that are not flat to start with - keep an eye on the non planar's

then and optimize to suit. Two of my other tutorials - the ones on optimizing meshes and

smoothing will also be good reading and recommended.

Hopefully you have gleaned some understanding and some golden rules I

hope from this short tutorial - these are accepted principles and practices in the real world

of generic wide spectrum studio modeling. I hope you use them to good effect.